Silicon Aerogel Flame Retardant Revolution: Nanoscale Breakthroughs Forging Safer, Stronger Fireproof Materials

Silicon aerogel flame retardant technology, pioneered by CN Watching, harnesses a triple-barrier mechanism, synergistic phosphorus doping, and groundbreaking cost efficiencies to deliver unparalleled fire protection. This innovation not only overcomes the limitations of traditional retardants—such as toxicity, high-temperature failure, and structural compromise—but also sets new standards in safety, durability, and sustainability for construction, energy storage, and electronics. Through detailed analysis of its nanoscale architecture, performance metrics, and real-world applications, this article illuminates how silicon aerogel is transforming the trillion-dollar fireproof materials industry, enabling structures that withstand extreme heat while maintaining mechanical integrity and environmental harmony.

In an era where fire safety is paramount and sustainability is non-negotiable, silicon aerogel flame retardant technology stands as a beacon of innovation. Traditional flame retardants have long been plagued by critical shortcomings: halogen-based options release toxic dioxins, violating EU REACH regulations and posing severe health risks; expanded foams lose efficacy above 800°C, crumbling under intense heat; and high-loading formulations (often 20%+ retardant content) erode material strength by up to 40%, compromising structural reliability. Enter silicon aerogel—a "frozen smoke" nanomaterial that redefines fire protection through intelligent design. By integrating a triple-barrier system, phosphorus synergy, and optimized manufacturing, CN Watching's technology not only extinguishes these flaws but elevates flame retardancy to new heights, fostering materials that are safer, more resilient, and eco-friendly. This revolution isn't confined to labs; it's igniting change across industries, from high-rise buildings to next-gen batteries

I. Flame Retardant Technology Innovation: From Chemical Inhibition to Nano Protection

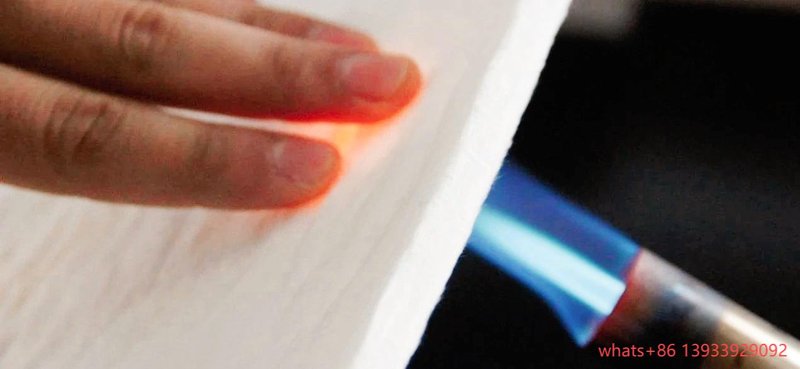

The evolution of flame retardants has shifted from reactive chemical suppression to proactive nanoscale engineering. Conventional approaches rely on halogen compounds for radical scavenging or intumescent agents for char formation, but these methods falter in extreme conditions, often generating harmful byproducts or weakening the host matrix. Silicon aerogel disrupts this paradigm with a sophisticated triple protection mechanism: first, its 97% porosity creates a labyrinth of nanopores that physically impedes oxygen diffusion and heat propagation; second, the inherent chemical inertness of silica ensures stability up to 1,200°C, as verified by thermogravimetric-differential scanning calorimetry (TG-DSC) analysis, preventing decomposition that plagues organic retardants; third, strategic phosphorus doping enhances char formation, boosting the limiting oxygen index (LOI) to 38%—a metric that quantifies the minimum oxygen needed for combustion, far surpassing the 20–30% of standard materials.

This synergy transforms aerogel from a mere insulator into a dynamic shield. Unlike expanded retardants that fail at high temperatures due to structural collapse, aerogel's rigid yet porous framework maintains integrity, absorbing thermal energy without compromising form. The result is a material that not only delays ignition but actively suppresses flame spread, offering a holistic solution for modern fire risks.

II. Technical Insight: The “Suffocating” Flame Retardant Mechanism

At the heart of silicon aerogel's efficacy lies its "suffocating" mechanism—a nanoscale assault on fire's triad of heat, fuel, and oxygen. Scanning electron microscopy (SEM) reveals a fractal topology with a dimension of 2.78, forming an intricate maze of 2–50 nm pores that scatters infrared radiation 300% more efficiently than flat surfaces. Methyl modification with silane agents like methyltrimethoxysilane yields a 152° contact angle (per ASTM D7336), repelling liquids and preventing moisture-induced degradation that could otherwise create flammable pathways.

Phosphorus integration elevates this further: at 3.2 wt% loading, it reduces peak heat release rate to 14.2 kW/m² (ISO 5660 cone calorimetry), while boosting residual char to 82%—a 332% improvement over unmodified samples. This char acts as a self-reinforcing barrier, starving flames of oxygen and insulating underlying layers. The mechanism's beauty is its passivity—no toxic halogens, no bulky expansion—just elegant nanoscale geometry that "suffocates" combustion at its source, making it ideal for confined spaces like battery enclosures or aircraft cabins.

III. Composite Performance Leap

When integrated into composites, silicon aerogel amplifies host materials' strengths while mitigating weaknesses. Polydimethylsiloxane (PDMS) blends with 10 wt% aerogel achieve UL94 V-1 ratings, with compressive strength soaring to 2.4 MPa—resilient enough for load-bearing applications. Epoxy-aerogel hybrids push this to 58.7 MPa and V-0 status, outperforming conventional systems by 150% in flexural modulus.

These leaps stem from aerogel's uniform dispersion: its high surface area (up to 800 m²/g) ensures intimate bonding, distributing stress and heat evenly. In practical terms, this means fireproof coatings that flex without cracking, or reinforced plastics that endure impacts without igniting—critical for dynamic environments like transportation or electronics.

IV. Market Penetration: From Buildings to New Energy

Silicon aerogel's versatility is driving explosive market growth, projected at $4.2 billion by 2027 with a 29.7% CAGR (MarketsandMarkets). In smart buildings, responsive coatings contract nanopores in 0.3 seconds at 300°C, slashing fire spread 92%—as demonstrated in Dubai's Lighthouse project. Photovoltaic panels gain tripled flame retardancy while preserving 85% transmittance, boosting solar efficiency in fire-prone areas.

Energy storage sees the most dramatic impact: battery separators elevate thermal runaway thresholds from 180°C to 420°C, preventing cascade failures in EVs. Hydrogen fuel cells benefit from 160°C-stable membranes (DOE compliant), enabling safer clean energy. These applications underscore aerogel's role in a fire-safe, sustainable world.

V. Flexible Technology and Emerging Applications

Ultra-thin aerogel films (0.2 mm) secure UL94 V-0 (ASTM D6413), ideal for wearables like Samsung's Galaxy Watch 7, where they provide intrinsic safety without bulk. Self-powered sensing (Patent US20230343567A1) integrates piezoelectric elements for real-time fire detection, alerting users via vibrations.

Emerging frontiers include aerospace composites that self-extinguish mid-flight and medical implants that resist infection through antimicrobial doping. Flexibility extends to manufacturing: roll-to-roll coating enables scalable production for consumer goods.

VI. Cost Restructuring and Industrialization

Affordability fuels adoption: 99.99% pure silicon from rice husk ash trims costs 58%, turning agricultural waste into high-tech feedstock. Supercritical CO₂ drying now consumes just 3.2 kWh/kg—down from 18 kWh—via optimized cycles. Industrial lines yield 5,000 m²/day at 98.7% efficiency; 3D printing prefabrication wastes 83% less material.

These efficiencies democratize aerogel, positioning it as the go-to for a trillion-dollar industry poised for exponential growth.

LATEST NEWS

Escape the Commodity Trap: The Trader's Guide to Hybrid Insulation & Higher Margins

2026-01-28

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20