Aerogels: Nanostructural Mastery to Future Frontiers – Classification, Innovations, and Application Transformations

Published: 2025-03-14

| Updated: 2025-11-11

Aerogel Insulation Solutions

Aerogel, the Guinness-certified "lightest solid" with densities as low as 3 kg/m³ and up to 99.8% porosity, is redefining materials science through its exceptional thermal conductivity (0.013 W/m·K) and vast surface area (up to 1,200 m²/g). From Samuel Kistler's 1931 invention to NASA's Mars missions and MIT's 2025 scalable 3D-printing breakthroughs, aerogel is evolving into a trillion-dollar powerhouse. This comprehensive exploration delves into its nanostructures, diverse classifications, cutting-edge preparation techniques, transformative applications, and a forward-looking roadmap through 2032, highlighting its role in sustainable innovation.

Aerogel stands as a testament to human ingenuity in manipulating matter at the nanoscale, transforming a seemingly fragile "solid smoke" into a versatile material driving advancements across industries. Its three-dimensional network of interconnected nanoparticles creates a labyrinth of pores that defy conventional physics, enabling properties like extreme lightness, superior insulation, and multifunctional adaptability. As of 2025, with markets projected to exceed $5 billion by 2027 per Grand View Research, aerogel is no longer a lab novelty but a cornerstone of energy efficiency, aerospace resilience, and environmental sustainability.

The Nanostructural Essence: Defining Aerogel's Unparalleled Properties

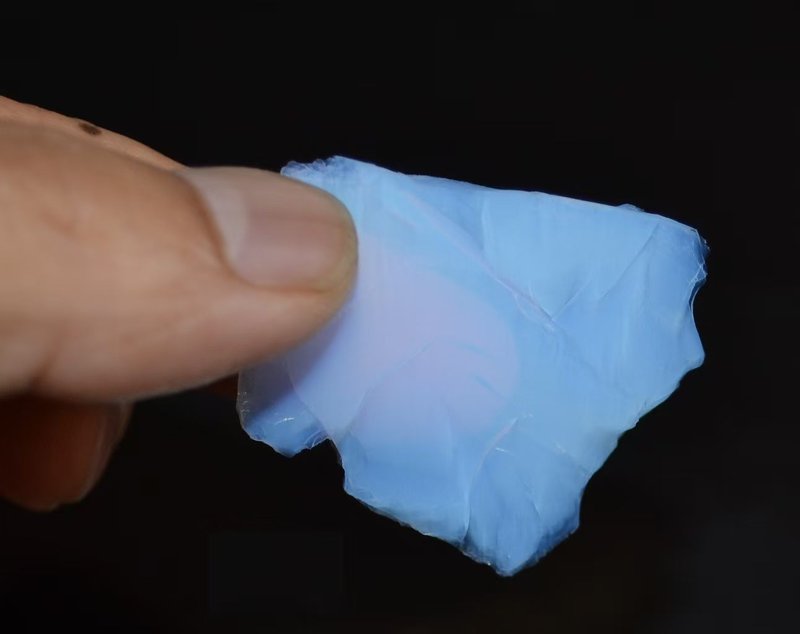

At its core, aerogel is a highly porous solid derived from a gel where the liquid component is replaced by gas, resulting in a structure that's 95–99.8% air. This nano-network—typically featuring pores of 2–50 nm and skeletal strands as thin as 1–10 nm—confers Guinness World Record-holding lightness (down to 0.001 g/cm³) alongside 15 key advantages: thermal conductivity rivaling vacuum (0.013 W/m·K), surface areas up to 1,200 m²/g for superior adsorption, and mechanical tunability from brittle monoliths to flexible composites.

Visualize the microstructure: a fractal-like scaffold where silica or carbon chains interweave, trapping air in cages smaller than the mean free path of gas molecules. This "Knudsen effect" slashes gaseous heat transfer, while phonon scattering in the skeleton minimizes solid conduction—making aerogel 2–5 times more insulating than fiberglass or foam.

Historical Milestones: From Lab Curiosity to Global Enabler

The aerogel story begins in 1931 with Samuel Kistler's silica synthesis via supercritical drying, a process refined in the 1980s at Lawrence Berkeley National Laboratory to eliminate capillary collapse. NASA's adoption in the 1990s for Stardust comet missions marked its space debut, capturing cosmic dust without shattering. By 2016, aerogel insulated the Perseverance rover on Mars. In 2023, MIT unveiled 3D-printing techniques for custom shapes, and as of 2025, scalable production via ambient-pressure methods has democratized access, fueling applications in Tesla's battery packs and CATL's Kirin cells.

Classification Decoded: Tailoring Properties for Purpose

Aerogels are categorized by composition, each subclass unlocking unique capabilities through nanostructural engineering.

Inorganic Aerogels: Robust Foundations for Harsh Environments

Silica aerogels dominate, with the Chinese Academy of Sciences' 2022 flexible, self-cleaning variant enhancing durability via hydrophobic coatings. Preparation routes vary: tetraethyl orthosilicate (TEOS) with supercritical CO₂ yields 0.018 W/m·K; sodium silicate ambient drying hits 0.025 W/m·K; eco-friendly rice husk ash freeze-drying achieves 0.022 W/m·K. Metal oxides like alumina endure 1,600°C for turbine blades, while zirconia advances nuclear shielding with radiation-resistant lattices.

Organic Aerogels: Flexibility Meets Sustainability

Organic variants prioritize bendability and biodegradability. Aspen Aerogels' polyimide types offer compressive recovery up to 90%, ideal for wearable tech. VTT Finland's cellulose aerogels, derived from wood pulp, decompose naturally—addressing environmental concerns. These materials excel in oil-spill cleanup, absorbing 200× their weight, and in biomedical scaffolds for drug delivery.

Carbon Aerogels: Conductive Powerhouses

Carbon aerogels shine in energy storage. Anti-oxidation coatings (SiC/TiO₂) extend temperature tolerance to 800°C, while graphene hybrids triple specific capacitance to 500 F/g. Tesla's 2023 Model S incorporated carbon aerogel electrodes for faster charging; by 2025, CATL's integrations in EV batteries enhance safety via thermal barriers.

Composite Aerogels: Hybrid Synergies for Advanced Functionality

Composites fuse strengths: SiO₂@Al₂O₃ core-shells gradient thermal resistance; graphene/polyimide networks boost electrical conductivity for sensors; SiC/CNT variants feature in China's J-20 stealth coatings, absorbing radar waves. These tailored hybrids enable multifunctional roles, from electromagnetic shielding to catalytic supports.

Preparation Innovations: Scaling from Lab to Factory

The evolution of aerogel synthesis revolves around six pillars: refined sol-gel chemistry for precise gelation; supercritical drying for pore preservation; ambient-pressure alternatives reducing costs 60%; 3D printing for complex geometries; molecular self-assembly for ordered structures; and AI-optimized parameters predicting outcomes via machine learning.

Globally, the U.S. leads with Aspen Aerogels' fiber-reinforced blankets; China's Guangdong Elison scales ambient drying to 10,000 tons/year; Germany's BASF pioneers bio-based precursors from lignin, aligning with EU sustainability directives.

Trillion-Dollar Horizons: Applications Reshaping Industries

Aerogel's market, forecasted at a 12.2% CAGR through 2035 by IDTechEx, spans sectors. In new energy, CATL's Kirin batteries use aerogel for fire suppression; Longi's PV modules employ it for sealing against humidity. Frontier tech sees NASA's 2025 aerogel in Artemis missions for habitat insulation; deep-sea explorers insulate 10 km submersibles against crushing pressures. Civilian innovations include smart clothing with phase-change aerogels for temperature regulation and energy-saving glass reducing building HVAC loads 40%.

Vision 2025–2032: Emerging Paradigms

By 2025, commercial biodegradable aerogels from cellulose will mainstream eco-products. 2028 heralds self-repairing variants with microcapsules sealing cracks. 2030 targets quantum-dot composites for optoelectronics, enhancing LED efficiency. By 2032, in-situ space manufacturing—printing aerogel habitats on the Moon—becomes feasible. Supported by the EU's "Aerogel 2030" initiative and China's 14th Five-Year Plan, these advancements position aerogel as a pivotal force in achieving carbon neutrality.

In essence, aerogel's journey from nanostructural marvel to ubiquitous enabler underscores a profound shift: mastering the invisible voids between atoms unlocks macroscopic revolutions, promising a lighter, cooler, and more efficient world.

Related Insulation Solutions

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19