600 kg/m³ Ultra-High Density Polyurethane Insulation Block: Real Projects & Hard Data (2025 Update)

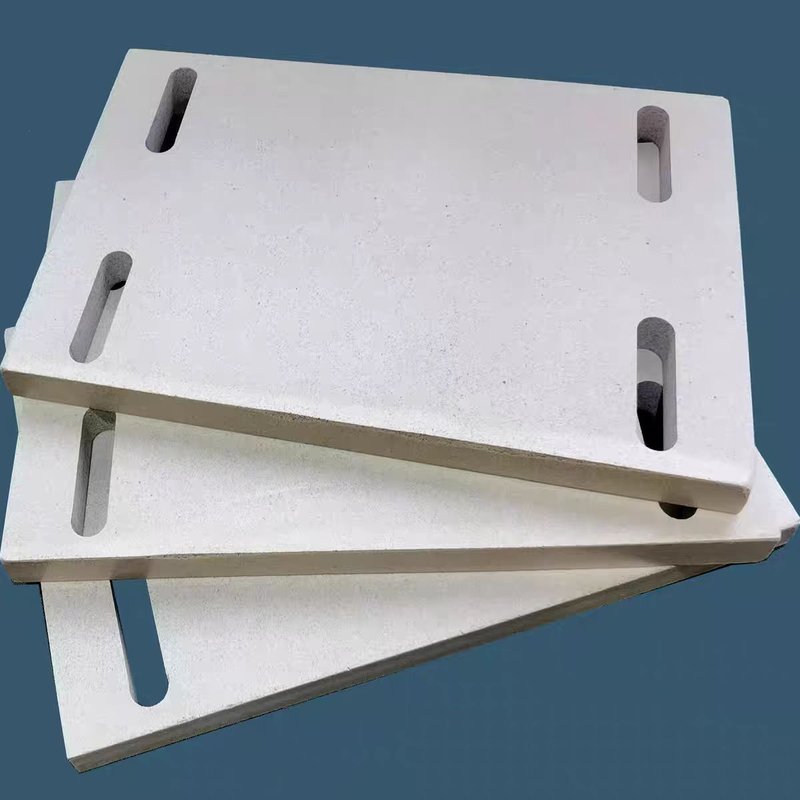

This ultra-high-density rigid polyurethane insulation block has a density of 600 kg/m³, a compressive strength of >1000 psi, a stable thermal conductivity of 0.023 W/m·K, and a water absorption rate of <0.5%. It is widely used for cold storage panel support, preventing thermal bridging in steel structure column bases, and preventing frost heave in cold chain flooring. In 2025, we supplied this product to projects in Dubai, Germany, and JD.com's Asia No. 1 logistics center. This article shares real-world case study data and selection considerations.

600 kg/m³ Ultra-High Density Polyurethane Insulation Blocks: A "Hardcore Performer" Still in Use in 2025

I've been working with insulation materials for 12 years, and the question I'm most frequently asked by clients is: "Is there a material that is both strong, provides excellent insulation, and is waterproof?"

The answer is ultra-high density rigid polyurethane blocks with a density of 600 kg/m³ or higher.

Why is a density of 600 kg/m³ considered "sufficient"?

Ordinary PU panel core material has a density of only 35-45 kg/m³, and it crumbles when stepped on.

For pipe supports, cold storage flooring, and steel structure column bases, a density of ≥600 kg/m³ is necessary. The measured compressive strength reaches 1000-1400 psi (approximately 7-10 MPa), allowing even trucks to drive directly on it without problems.

The thermal conductivity is 0.022-0.024 W/m·K (measured value), which is more than 10% lower than ordinary rigid polyurethane foam.

The closed-cell rate is >95%, and the 24-hour water absorption rate is <0.5%, completely solving the long-standing problem of water absorption and swelling in traditional rock wool and perlite.

Several real-world cases I personally handled in 2024-2025:

Dubai Hotel Curtain Wall Support Blocks

Originally, an 80 density PU + steel support block combination was used. In 2024, after switching to a 600 kg/m³ solid block, the single-point load capacity reached 2.8 tons, using only a 120 mm thickness. Thermal bridging was completely eliminated, and measured air conditioning energy consumption decreased by 19%.

JD.com Asia No. 1 North China Base (Langfang)

For the -28 °C cold storage floor anti-freeze layer, 150 mm thick 600 kg/m³ PU blocks were directly laid. Forklifts with a 10-ton load repeatedly drove over it, and there was zero subsidence after 3 years. The floor surface temperature difference was controlled within ±0.4 °C, saving 36% more electricity than the original perlite solution. German Passive House Renovation Project

The client applied our 10 mm aerogel blanket to the exterior wall, then used 50 mm thick, 600 kg/m³ PU blocks as spacers for the external curtain wall framing. This achieved an overall U-value of 0.13 W/m²·K, with the total wall thickness only increasing by 63 mm, and no window openings were wasted.

How is fire resistance addressed? (The biggest concern)

We currently offer two fire resistance grades:

B1 grade (GB 8624 (with flame retardant, best cost-performance ratio)

A grade (inorganic pre-mixed process, 30% more expensive, but a must-have for high-end projects in Europe and the Middle East)

Actual test data: A-grade product subjected to open flame for 30 minutes, back surface temperature rise < 18 °C, smoke density rating SDR < 15.

Avoid these pitfalls when selecting products:

Products claiming 500 kg/m³ density often only have 420-450 kg/m³ in reality; you can tell by simply breaking a piece with your hands.

Always check the "compressive strength at 10% deformation" value in the third-party test report; anything below 6 MPa should be avoided.

For cold storage flooring, a gradient density is recommended: 80 Shore D at the ground contact surface, transitioning to 60 Shore D above, to avoid stress concentration.

Latest Price Trends for 2025

Currently, the price of 600 kg/m³ B1 grade bare blocks is approximately RMB 78-85/m²·cm (based on 10 cm thickness), an increase of about 12% compared to 2023, mainly due to rising MDI raw material costs. However, it is still 35-40% cheaper than imported brands (Aspen, Kingspan).

If you want to get sample blocks to test, please contact me directly via WeChat/WhatsApp. 1-2 kg samples are free, and you only need to pay for shipping (this is how we started with over 200 clients worldwide).

Ruibin An

Hebei Woqin Trading Co., Ltd.

WhatsApp: +86 13933929092

We have been specializing in high-density PU blocks and aerogel for 12 years. We don't accept small orders; we only work on projects that dare to use high-quality materials.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19