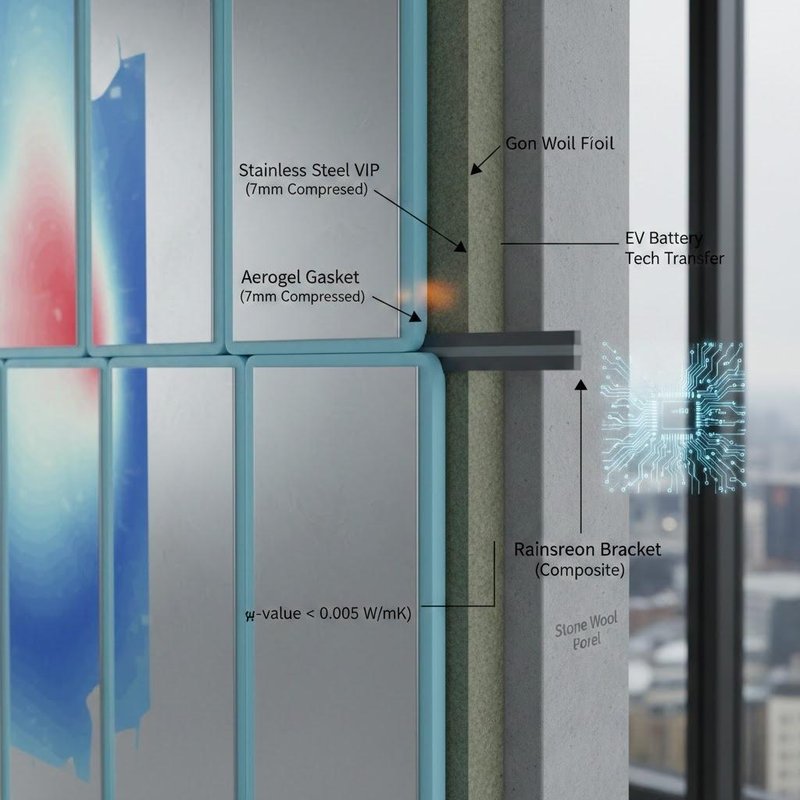

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

When 13 years of "Insulation Valley" heritage meets the rigorous demands of UK technical consultancy, a cross-border debate on VIP edge detailing begins. From confessing the 1% industry failure rate to introducing laser-welded stainless steel foils and achieving a Psi-value drop from 0.012 to 0.005 (based on ISO 10211), this is more than a material upgrade—it is a manifesto on space, compliance, and architectural integrity.

I. The Prelude: A Midnight Email from London

In the early hours of the morning, an email landed in my inbox from a highly respected technical consultant in London. We weren't discussing bulk orders; we were debating a detail that makes most manufacturers look away: How do we eliminate the thermal bridge at the edge of a Vacuum Insulation Panel (VIP) without adding a single millimeter of thickness?

II. The Power of Honesty: That "Missing" 1%

During our exchange, I admitted a reality the industry often hides: even with top-tier QC, aluminized plastic VIPs face a roughly 1% failure rate in the field.

"Admitting imperfection is the starting point for seeking perfection." This transparency built immediate trust. Because only through honesty can we discuss the real solution: If stainless steel foils can provide a 50-year lifespan, who will mitigate the slight thermal conductivity spike at the welded edge?

III. Strategic Transfer: From EV Batteries to Heritage Retrofit

My colleague was curious about ultra-thin stainless steel welding. I explained that this technology is a strategic transfer from China’s massive EV battery supply chain.

When high-precision laser welding—designed to protect energy density in batteries—is applied to building insulation, we get more than an absolute vapor barrier; we get a material with the durability the European sector demands. This is the "technology dividend" of a matured global industrial chain.

IV. Surgical Precision: The 0.005 W/mK Breakthrough

To address the "Performance Gap" on-site, we proposed the "Aerogel Gasket" concept.

We factory-bond a 7mm compressible Aerogel strip to the square edges of the VIPs. Based on our preliminary thermal modeling (ISO 10211), this hybrid system can reduce the linear thermal transmittance (Psi-value) from a conventional 0.012 W/mK to 0.005 W/mK or lower—effectively closing 60% of the performance gap. This "Technical Forgiveness" allows the panels to be installed non-sequentially, handling site tolerances that rigid systems cannot.

V. The Dignity of Space: The 150mm Threshold

We discussed the "Valuation of Space." In high-density cities like London, a 150mm difference in wall thickness often determines whether a social housing project remains compliant, or whether a family is forced to move.

We aren't just selling insulation; we are recovering lost floor area and protecting the spatial dignity of the residents.

VI. Epilogue: The Long Journey of an Insulation Man

He asked me why I am so obsessed with these details.

I told him: I grew up in China’s “Insulation Valley”—a region that supplies thermal materials to half the country's construction sites. This craft is in my blood. 13 years on-site taught me one thing: the devil is always in the joint details.

Our current solution isn't "perfect" yet, but we have proven a better path exists. If you are losing sleep over a 5mm thermal bridge on your project, send us your junction detail. We don’t promise a perfect answer—but we promise to walk that 0.005 with you.

The road is long, and we are just getting started.

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05