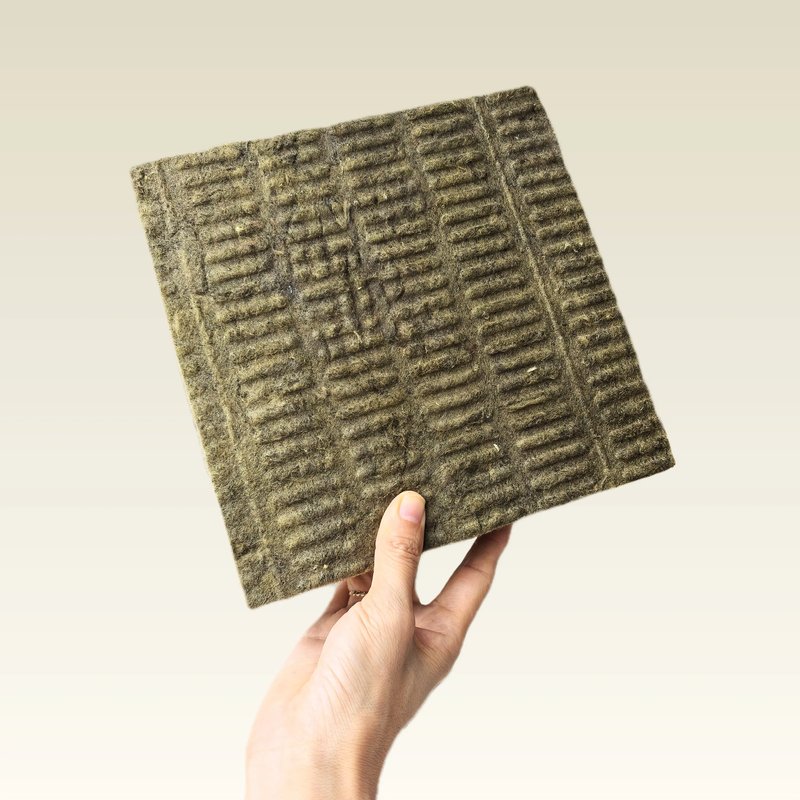

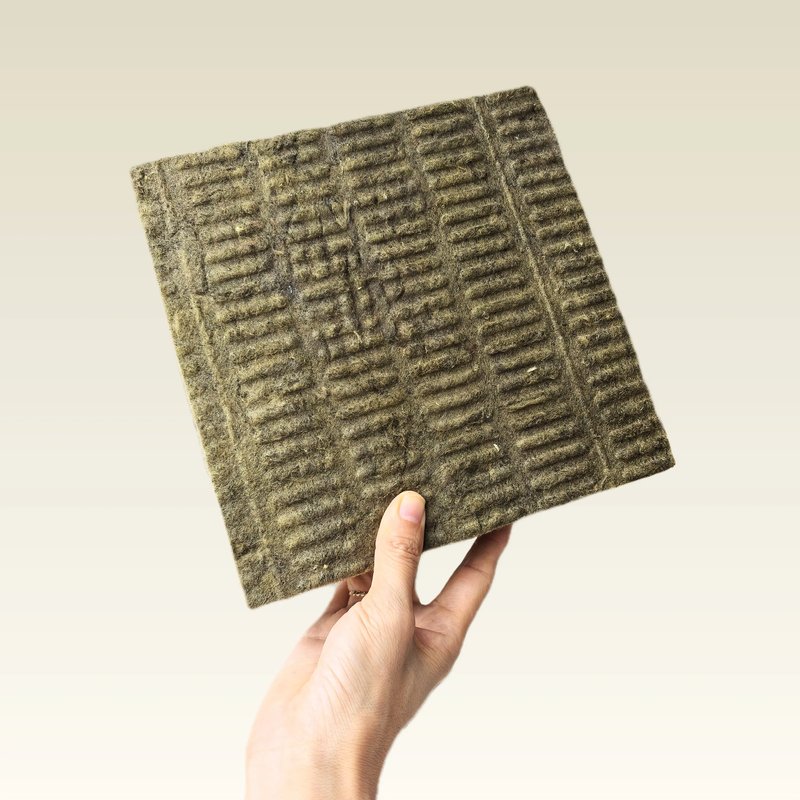

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

PRODUCT INTRODUCTION

Professional grade alumina-silicate fiber blanket verified by Lab Report . Features extreme thermal stability with only -1.5% linear shrinkage at 800°C. Engineered for heavy-duty industrial applications requiring high tensile strength (44 kPa) and low thermal conductivity (0.134 W/m·K).

| Item | Technical Index (Result) | Standard / Condition |

|---|---|---|

| Bulk Density | 107 kg/m3 | Average Value |

| Tensile Strength | 44 kPa | Average Value |

| Thermal Conductivity | 0.134 W/(m⋅K) | @ 500∘C |

| Linear Shrinkage | −1.5 % | @ 800∘C×24h |

| Slag Ball Content | 11.6 % | Φ>0.212mm |

| Moisture Content | 0.2 % | Max |

| Fire Rating | Class A1 (Non-combustible) | High Temp Resistance |

【Core Technical Data - Verified by National Testing Center】 We provide facts, not just claims. Based on the latest testing from the Zibo Municipal General Institute of Inspection and Metrology:

- Classification Temperature: 1260°C (Standard Grade).

- Thermal Stability: -1.5% Permanent Linear Change after 24 hours at 800°C.

- Insulation Efficiency: Thermal Conductivity is 0.134 W/(m·K) at a mean temperature of 500°C.

- Mechanical Durability: 44 kPa Tensile Strength ensures the blanket stays intact under vibration.

- Material Purity: Low shot content (>0.212mm) of 11.6% for maximum thermal resistance.

- Standard Density: 107 kg/m³ optimized for industrial heat storage.

【Key Industrial Applications】 Designed for environments where standard insulation fails:

- Mining & Heavy Machinery: Heat shields for high-temperature engines and exhaust systems.

- Petrochemical & Power: Lining for boilers, high-temperature pipes, and steam turbines.

- Metallurgy & Kilns: Expansion joint seals and backup insulation for industrial furnaces.

- Composite Systems: The perfect primary layer for "Ceramic Fiber + Aerogel" hybrid insulation solutions.

【Authority & Quality Assurance】

- Certified Testing: Every batch is traceable to official test reports .

- International Standards: Manufacturing follows GB/T 16400-2023 and GB/T 17911-2018 testing protocols.

- Project Reliability: Trusted for mission-critical cooling, such as our composite solution for Brazilian mining equipment operating at constant 800°C.

【Why Choose Our Ceramic Fiber?】 Unlike low-quality alternatives that shrink and crack at high temperatures, our needle-punched blankets maintain their structural integrity. The low shot content means you get more actual fiber per cubic meter, resulting in a lighter, more efficient thermal barrier.

Fast Quote

Get a price for High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

CONTACT US

RELATED PRODUCTS

NEW

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity,...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using...

Glass Wool Insulation: Professional Grade Thermal & Acoustic Solutions for Heavy Industry

Engineered for thermal and acoustic precision,...

RELATED PRODUCTS

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity, our Graphite EPS Sub-frame...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using our advanced low-slag...

Glass Wool Insulation: Professional Grade Thermal & Acoustic Solutions for Heavy Industry

Engineered for thermal and acoustic precision, Hebei Woqin’s Industrial...