Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

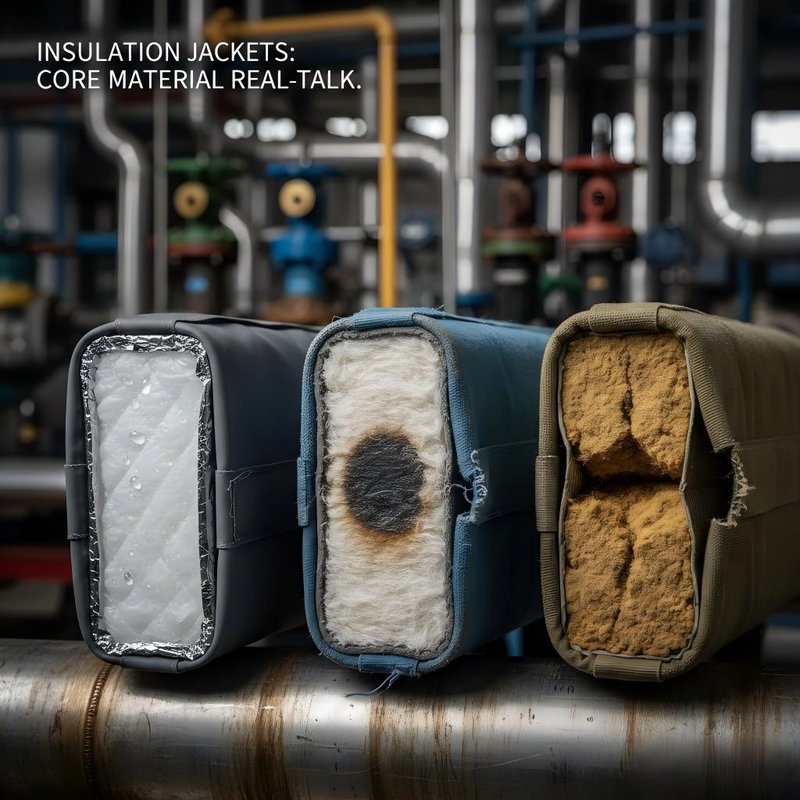

Why do valve insulation jackets often fail within a year? Beyond fabric wear, the real weakness lies in the "Core." Traditional rockwool is too bulky for tight spaces, while fiberglass fails when wet. Based on lab data, this guide compares Aerogel against traditional materials to help you make the right choice for space-constrained and corrosive environments.

In industrial thermal systems, insulating valves, flanges, and pumps has always been a headache. Removable Insulation Jackets (also known as soft covers or pads) have become the standard solution due to their flexibility and ease of maintenance.

However, many facility owners find that these jackets often cost more in the long run than expected. They are either too bulky to fit into tight pipe racks, or they are not waterproof, leaving the equipment soaking in rusty water when removed.

The root of the problem lies not in the outer silicone fabric, but in the internal "Core Insulation Material."

Today, based on laboratory test data, we compare three mainstream core materials: Aerogel Blanket, Traditional Rockwool, and Fiberglass Needle Felt, to determine which is the "Ultimate Core" for industrial jackets.

Round 1: The Battle of Space & Thickness

In complex heat exchange stations or compact equipment rooms, the gap between pipes is often just a few centimeters. This is the ultimate challenge for insulation thickness.

- The Traditional Way (Rockwool/Fiberglass): According to test data, the thermal conductivity of Rockwool and Fiberglass at ambient temperature is typically between 0.034 - 0.044 W/(m·K). To meet personnel protection standards (Surface Temp <50℃), the insulation layer usually requires a thickness of 40mm - 60mm.The Consequence: The jacket becomes a "Bloated Quilt." It not only obscures the view of gauges but frequently interferes with valve handwheels, making operation and installation impossible.

- The Woqin Aerogel Advantage: Lab data shows our Aerogel Blanket achieves a thermal conductivity as low as 0.020 W/(m·K) (@25℃). This means it requires only 1/3 of the thickness of traditional materials to achieve the same thermal resistance.The Result: An ultra-thin thickness of 10mm - 15mm perfectly contours to irregular equipment, completely eliminating installation interference in tight spaces.

Round 2: Hydrophobicity vs. CUI (Corrosion Under Insulation)

Water is the enemy of insulation. Soft jackets inevitably face rainwater wash-downs or steam leaks.

- The Traditional Way (The Sponge Effect): Rockwool and standard needle felts are hydrophilic. Once water penetrates through stitching needle holes, the core acts like a sponge. Since water conducts heat 20 times faster than air, wet insulation not only fails thermally but traps moisture against the hot metal, leading to severe Corrosion Under Insulation (CUI). Often, you don't know the pipe is rotting until it leaks.

- The Woqin Aerogel Advantage (The Hydrophobic Shield): According to the GB/T 10299-2011 standard test, our Aerogel Blanket maintains a hydrophobicity rate of ≥99.7%.The Result: Even if the outer fabric is torn, liquid water cannot penetrate the insulation core. This "Lotus Effect" keeps the pipe surface dry, physically cutting off the path for CUI and significantly extending asset life.

Round 3: Vibration & Durability

Removable jackets endure harsh conditions: they are frequently stripped off, folded, stepped on, and subjected to pipe vibration.

- The Traditional Way (Sagging & Settling): The short-fiber structure of Rockwool tends to "settle" under long-term vibration. The insulation packs down to the bottom of the jacket, leaving an empty air pocket at the top (thermal bridging). After a few removal cycles, the core often breaks or turns to powder.

- The Woqin Aerogel Advantage (Flexible & Tough): Test data indicates that the vibration mass loss rate of Woqin Aerogel Blanket is only 0.3% (far superior to the national standard requirement of ≤1.0%).The Result: Its high-density, integrated flexible structure makes it tough like leather. Even after 100+ removal cycles, it retains its shape and thermal performance without sagging or thickness loss.

Selection Guide: What to Use and When?

We don't advocate for "buying the most expensive," but rather "buying the right fit." Based on real-world comparisons, here is our selection guide:

| Comparison Metric | Woqin Aerogel Blanket | Traditional Rockwool | Standard Fiberglass Felt |

| Thermal Conductivity | 0.020 W/(m·K) | ~0.043 W/(m·K) | ~0.040 W/(m·K) |

| Equivalent Thickness | 10mm (Ultra-thin) | 40mm | 35mm |

| Water Resistance | 99.7% Hydrophobic (Anti-CUI) | Absorbs Water | Absorbs Water |

| Vibration Stability | Excellent (Maintains Shape) | Poor (Settles/Powders) | Fair |

| Recommended For | Tight Spaces, High Humidity, Offshore, Complex Valves | Large Pipes, Dry Areas, No Space Limits | General Medium-Temp, Low Budget |

Conclusion

If your project has unlimited space and the environment is absolutely dry, traditional Rockwool remains a cost-effective choice.

However, if you are facing tight installation spaces, high humidity corrosion risks, or require frequent maintenance, Aerogel Insulation Jackets are the clear winner. They solve the "fitment headache" and prevent CUI, saving you significant labor and pipeline replacement costs over the asset's lifecycle.

Ready to upgrade your specifications?

Don't guess on the thickness. Send us your operating temperature and pipe diameter. Our engineering team will provide a free thermal calculation and material comparison table for your specific project.

[Contact Our Engineering Team]

Data Source: Hebei Woqin Trading Co., Ltd. Laboratory & Third-Party Test Reports.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07