The Future of Construction with Aerogel Material Advancements

The construction industry is on the brink of a revolution, thanks to cutting-edge aerogel technology.

The construction industry is on the brink of a revolution, thanks to cutting-edge aerogel technology. This ultralight material, composed of up to 99.8% air, is redefining thermal insulation standards and reshaping building practices worldwide. With its exceptional insulating properties, aerogel is poised to transform the way we design, construct, and maintain structures. As the thermal insulation coating market expands, aerogel manufacturers are at the forefront of innovation, developing products that promise to drastically improve energy efficiency in both residential and commercial buildings.

Table of contents:

How Aerogel Coats Are Transforming Modern Building Practices

Integrating Aerogel Thermal Insulation into Sustainable Architecture

Overcoming Traditional Insulation Challenges with Aerogel Technology

The Economic Impact of Widespread Aerogel Material Adoption in Construction

How Aerogel Coats Are Transforming Modern Building Practices

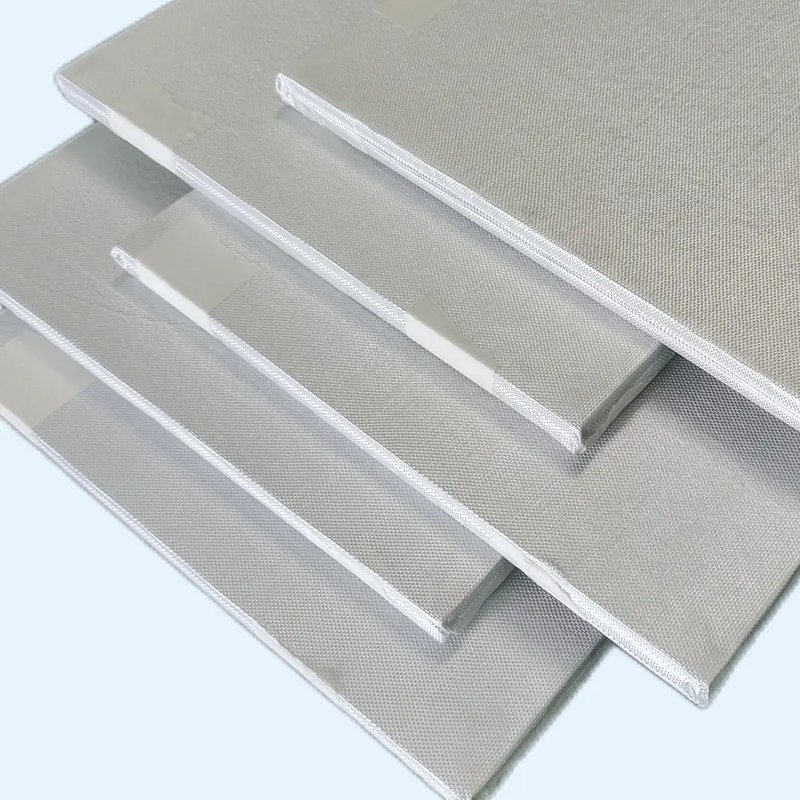

Aerogel manufacturers have developed advanced coatings that are revolutionizing the construction industry. These innovative products, such as InsulateWool's High-Efficiency Aerogel Coat, offer unparalleled thermal insulation with minimal thickness. With a thermal conductivity of just 0.013W/(m · K), a 2mm layer of aerogel coating provides insulation equivalent to 40mm of traditional materials. This breakthrough allows architects and builders to maximize interior space without compromising on energy efficiency. The thermal insulation coating market is seeing a surge in demand for these high-performance products, as they offer fire resistance, easy application through spraying or scraping, and exceptional durability with a lifespan exceeding 20 years.

Integrating Aerogel Thermal Insulation into Sustainable Architecture

The integration of aerogel coatings into sustainable architecture is gaining momentum as aerogel manufacturers continue to refine their products. These coatings are particularly valuable in retrofitting existing buildings, where space constraints often limit traditional insulation options. The nanoscale pores and 3D skeleton structure of aerogel materials contribute to their superior insulating properties, making them ideal for both interior and exterior applications. In the thermal insulation coating market, aerogel-based products are emerging as a go-to solution for architects focused on creating energy-efficient, environmentally friendly buildings. From moisture-proofing interiors to insulating roofs, doors, and windows, aerogel coatings offer versatile solutions that align with sustainable design principles.

Overcoming Traditional Insulation Challenges with Aerogel Technology

Aerogel technology is addressing many of the limitations associated with conventional insulation materials. Unlike traditional options, aerogel coatings can be applied in thin layers without sacrificing performance, making them suitable for a wide range of applications in both architectural and industrial settings. Aerogel manufacturers have developed specialized formulations that can withstand extreme temperatures, from -40°C to 800°C, opening up new possibilities for insulation in harsh environments. The thermal insulation coating market is benefiting from these advancements, as aerogel products offer superior protection against heat transfer, moisture, and corrosion. This versatility makes aerogel coatings an attractive option for diverse projects, from residential renovations to industrial equipment protection.

The Economic Impact of Widespread Aerogel Material Adoption in Construction

The growing adoption of aerogel materials in construction is poised to have significant economic implications. As more aerogel manufacturers enter the market and production scales up, the cost of these advanced materials is expected to decrease, making them more accessible to a broader range of projects. The thermal insulation coating market is witnessing increased competition and innovation, driving down prices while improving product performance. The long-term economic benefits of aerogel coatings are substantial, with case studies showing remarkable energy savings. For instance, petrochemical storage tanks treated with aerogel coatings have seen temperature reductions of 5-8°C and a 60% decrease in summer energy consumption. Similarly, residential renovations using aerogel products have resulted in 40% reductions in indoor humidity and 35% decreases in air conditioning usage.

The construction industry stands on the cusp of a transformative era, driven by the remarkable properties of aerogel materials. As aerogel manufacturers continue to innovate and expand their product offerings, the thermal insulation coating market is experiencing rapid growth and diversification. The adoption of these advanced materials promises not only to enhance building performance and energy efficiency but also to reshape architectural possibilities. With its ability to overcome traditional insulation challenges and deliver substantial economic benefits, aerogel technology is set to play a pivotal role in the future of sustainable, high-performance construction. As the industry embraces these innovations, we can expect to see a new generation of buildings that are more efficient, comfortable, and environmentally friendly than ever before.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19