Why 99% of Industrial Insulation Fails at 800°C: The Synergy That Redefines the Thermal Boundary

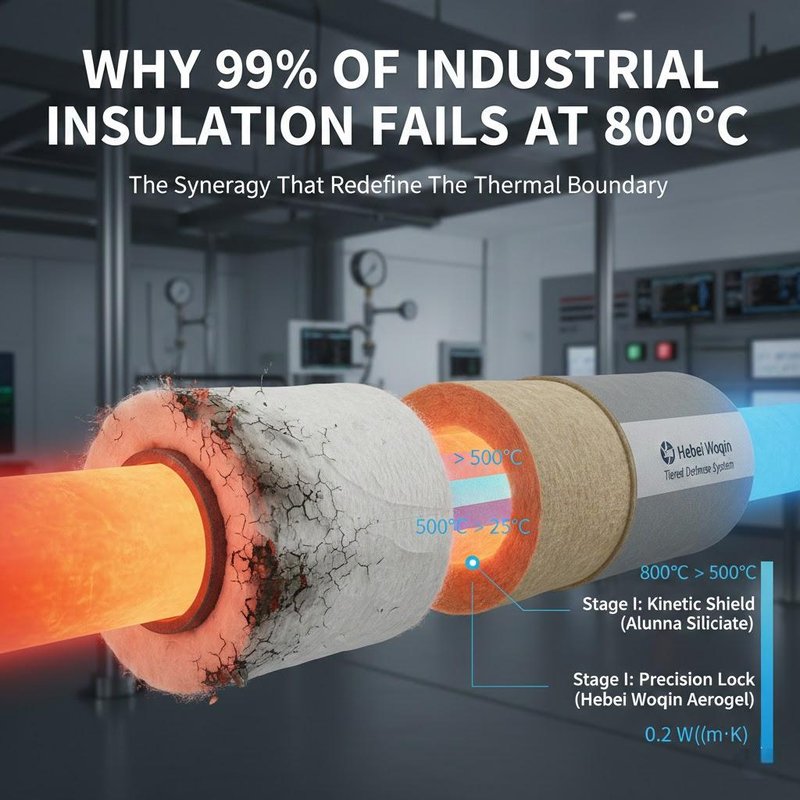

Conventional single-material solutions fail catastrophically at 800°C. The industry's search for a "magic material" is a thermodynamic trap. Hebei Woqin’s Tiered Defense System pairs an alumina silicate "Kinetic Shield" with an aerogel "Precision Lock" to reduce total thickness by over 50%. We engineer boundary control, not just materials.

The Thermodynamic Trap In industrial R&D, seeking a single material that is ultra-thin, ultra-insulating, and resists 800°C is a tactical error. If you deploy a Vacuum Insulation Panel (VIP) above 100°C, the internal film melts—vacuum lost. If you deploy a standard Aerogel blanket alone at 800°C, the nano-structure undergoes sintering. You aren't insulating; you are managing a slow-motion disaster.

Hebei Woqin: Engineering the Tiered Defense System At Hebei Woqin, we don't sell rolls of product. We design Boundary Control. Our strategy for the 800°C frontier—critical for mining and high-pressure steam—is a two-stage kinetic interception.

- Stage I: The Kinetic Shield (Alumina Silicate Blanket) The shield’s job isn't to be the best insulator, but the best survivor.Hebei Woqin Lab Data: Tested at 800°C for 24 hours, linear shrinkage is only -1.5%.The Result: It absorbs the brutal thermal energy, dropping the interface temperature to a "safe" 500°C for the next layer.

- Stage II: The Precision Lock (Hebei Woqin Aerogel) Once the temperature is buffered, the Aerogel executes the final lock.Hebei Woqin Lab Data: It maintains a thermal conductivity of 0.02 W/(m·K) at 25°C and a stable 0.039 even at 300°C.The Result: It provides surgical temperature control in the space the Shield protected.

The 50% Thickness Dividend This is where the math wins. By combining the structural stability of Alumina Silicate with the thermal density of Aerogel, we achieve what single-layer solutions cannot.

In the Hebei Woqin Laboratory, our composite benchmarks show a thickness reduction of over 50%. For space-constrained mining equipment or precision CNC enclosures, this is the difference between an operational asset and a thermal hazard.

Uncompromising Engineering Integrity We don't optimize for "good enough." Every hebei woqin system is built on a 99.7% hydrophobicity standard and a massive 1255 kPa transverse tensile strength.

Stop buying material. Start designing your thermal defense.

For projects facing the 800°C test: Contact Hebei Woqin for a System Insulation Profile Analysis. Let us calculate the thickness reduction for your specific layout.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Industrial Pipe Insulation: A Strategic Selection Framework Based on Thermal Risk & Asset Integrity

2026-02-03

The 80/20 Engineering Strategy: Solving the Critical 20% of Structural Thermal Bridges for Total Envelope Integrity

2026-02-01

Beyond Logistics: Why 8.115MPa PU & High-Mk Rock Wool is the Only "Risk-Hedged" Solution for Middle East Coastal EPCs

2026-02-01

The Hidden $50k Cost in Your Insulation Bid: Why Thermal Integrity Beats Price Per Meter

2026-01-31

Why 99% of Industrial Insulation Fails at 800°C: The Synergy That Redefines the Thermal Boundary

2026-01-30